General

MUCH more light than the stock bulb.

The stock 5W bulb emits roughly 25 lumens. My LED replacement

board is capable of up to 415 lumens (315 lumens 5000K white,

100 lumens red/orange), at roughly the same power consumption.

Separate red/orange activation (with no white).

Up to 100 lumens of red/orange light may be activated via the

new button installed in the windshield trim next to the dome light.

This is great for drive-throughs, toll booths or just lighting the

cabin to find something on the passenger seat or in the armrest.

It is much less detrimental to night vision than white light.

Dimming capability. The red/orange and white light may be dimmed using an external 10K potentiometer.

Long life.

The Luxeon Rebel LEDs are rated for 50,000 hours for 70% lumen

maintenance at 350mA and a junction temperature maintained at or

below 135C. I expect them to last well beyond the life of the

vehicle. Even if used for an hour every day, 50,000 hours is more

than 136 years.

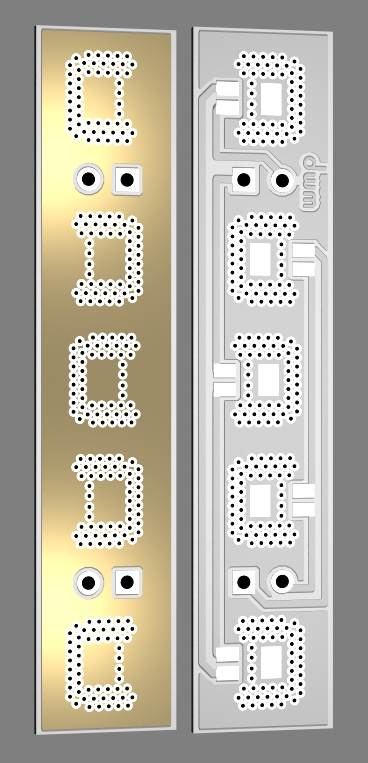

LED Board

Correctly dimensioned.

The board is sized to fit nearly perfectly in the dome light

compartment of the Z3 roadster and Z3 M roadster.

Careful consideration of thermals in design.

The Luxeon Rebel LED needs effective heatsinking. My board

design follows the Luxeon Rebel thermal design guidelines, though

the size of the vias is slightly larger (some PCB shops can't

handle holes of 20 mils or smaller). It also incorporates thermal

pours while still being only 2 layers (reduces PCB cost). The

back of the board is a full thermal pour, to which I attach

10mm deep finned aluminum heatsinks. The end result: the LEDs

should easily outlast the vehicle.

3 ounce copper over .032" FR-4.

3 ounces/sq.ft. copper is used on both sides of the board, and

the board is .032" thick instead of the usual .062". Combined,

this significantly improves heat transfer from the front of the

board to the back of the board as well as throughout the top

thermal pours. It is thermally competitive with MCPCB while

costing less. The 3 ounce/sq.ft. copper traces which carry current

have very low resistance while being narrower than the equivalent

1 ounce/sq.ft. traces. This permits a larger thermal pour.

White soldermask.

The white soldermask reflects light and is a cosmetic match to the

dome light housing when the dome light is off.

Direct wire-to-board connections.

While not fancy, directly soldering wires to the board avoids

concerns about thermal degradation of a header and conserves

precious space. As shipped, the board is wired to a 4-pole

connector that plugs directly into the control board.

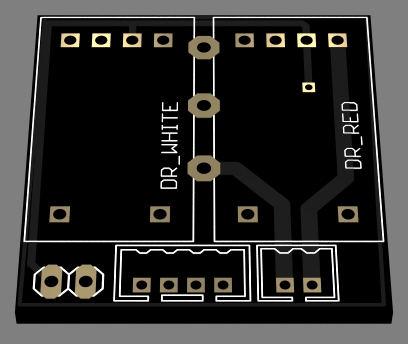

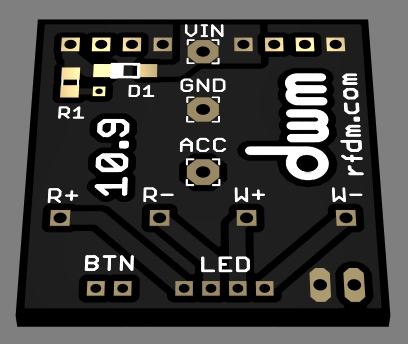

Control Board

Small.

Approximately 30mm long and 28mm wide, small enough to

fit inside the windshield trim.

Dimming input.

An external 10K potentiometer can be used to control the brightness

of the red and white LEDs. The dimming connection is just a .1"

pitch pin header; if dimming is not desired, a jumper is installed

on this header.

350mA LED drivers.

350mA LED drivers with dimming and closed-loop maximum current

control ensure long LED life.

2mm pitch headers for LED board and pushbutton connections.

Easily connect and disconnect the LED board and the pushbutton.

Direct wire-to-board for dome light input, accessory power and

ground.

As shipped, the control board will have long wires connected for

dome light input, accessory power and ground. This is the most

flexible solution for those who may have other wiring in their

windshield trim (accessory power for a ValentineOne, for example).